Automotive SPICE

What is Automotive SPICE?

Automotive SPICE is a process maturity framework to assess the capability and maturity of organisational processes to develop software resp. embedded systems in the automotive industry.

In the automotive industry the original equipment manufacturers (OEM) ((OEM refers to parts and manufacturers involved in the final assembly of a vehicle — in contrast to aftermarket parts that can be installed after the car comes out of the factory.)) and suppliers use Automotive SPICE to manage their product quality and their project success better.

Legal owner of the brand "Automotive SPICE" is the Quality Center of the German Association of the Automotive Industry (QMC, Quality Management Center in the German Association of the Automotive Industry).

Equal to any process maturity framework, Automotive SPICE consists of a process reference model (PRM) and a process assessment model (PAM) tailored to the needs of developing electronic devices in automobiles.

History of Automotive SPICE

Automotive SPICE was developed 2001 as a variant of ISO 15504 (SPICE) by the AUTOSIG (Automotive Special Interest Group). This group consists of the SPICE User Group, the Procurement Forum, and german automotive constructors: Audi, BMW, Daimler, Porsche, Volkswagen, and other international automotive manufacturers like Fiat, Ford, Jaguar, Land Rover, Volvo.

Process Reference Model HIS Scope 2005

The german automotive OEMs Audi, BMW, Daimler, Porsche and Volkswagen founded the initiative HIS (Herstellerinitiative Software, "Manufacture Initiative Software") to define a minimal set of processes, the so-called HIS scope. The HIS scope was released 2005.

Process Reference Model

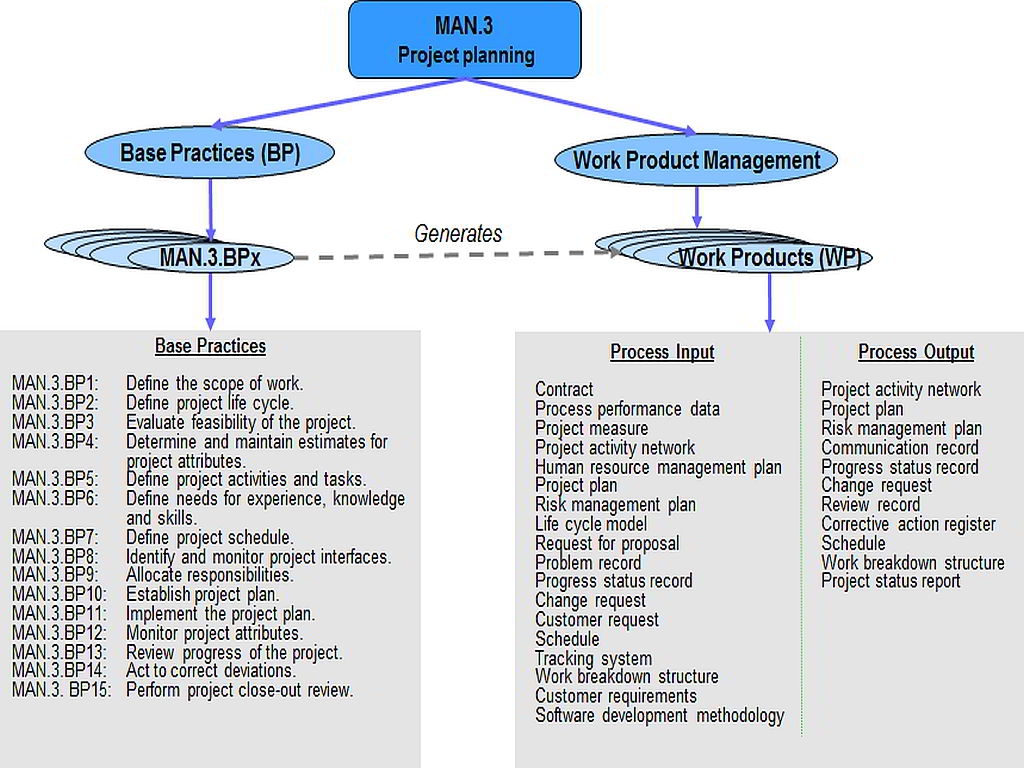

The process reference model (PRM) defines all Automotive SPICE processes to be applicable in well-defined automotive software and embedded systems development. A process reference model is a schema that guides you in a specific field of application to perform certain activities and to produce related work products. On the work floor level, it is a set of base practices (BP) and resulting work products (WP).

Base practices are specific for their field of application and they help to generate unique work products by certain process inputs.

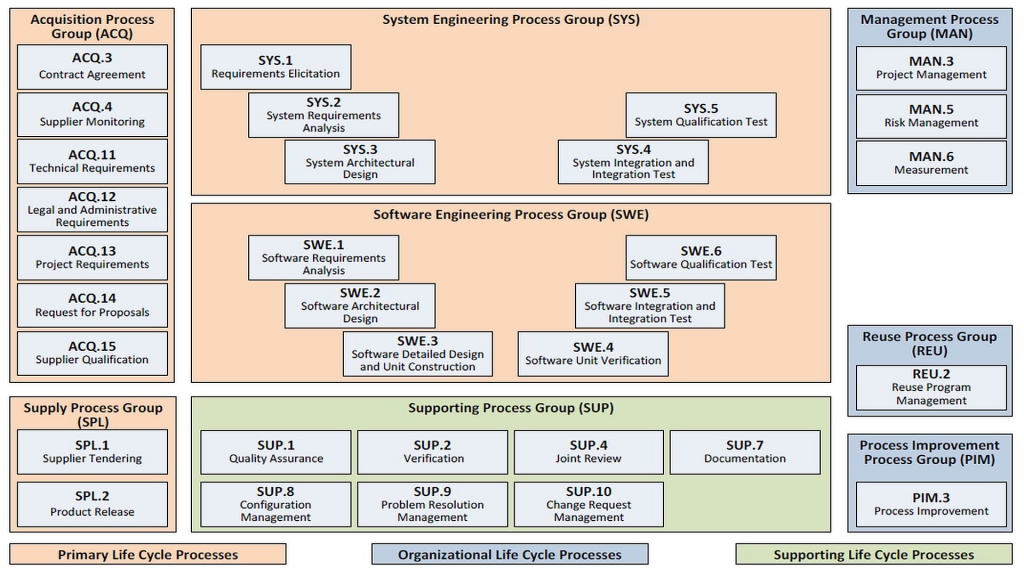

The processes are clustered by common topics — like acquisition, supply, and logistics — to so-called process areas. Automotive SPICE describes the life cycle of electronic products with three different process areas:

- Primary Life Cycle Processes — Acquisition (ACQ), Supply (SPL), and two engineering groups: System Engineering (SYS) and Software Engineering (SWE).

- Organisational Life Cycle Processes — Management (MAN), Reuse (REU): project and risk management, measurements, process improvement and operational reuse management.

- Supporting Life Cycle Processes — Supporting (SUP): quality assurance, verification, documentation, configuration managment, change request management, and problem resolution management.

Process Assessment Model

The assessment model (PAM) maps the extent of process performance to specific capability levels and defines how these levels can be assessed. Capability levels measure on a given scale the extent how far a process is performed.

Automotive SPICE assessments are conform to ISO/IEC 15504-2 assessment requirements. The assessments evaluate on six levels how an organisation is capable to run mature processes. The framework defines for each level specific capability indicators to measure the extent of achievement on a four-value rating scale.

| Scale | Description | ||

| N | Not achieved | 0 to ≤ 15% achievement | There is little or no evidence of achievement of the defined process attribute in the assessed process. |

| P | Partially achieved | > 15% to ≤ 50% achievement | There is some evidence of an approach to, and some achievement of, the defined process attribute in the assessed process. Some aspects of achievement of the process attribute may be unpredictable. |

| L | Largely achieved | > 50% to ≤ 85% achievement | There is evidence of a systematic approach to, and significant achievement of, the defined process attribute in the assessed process. Some weaknesses related to this process attribute may exist in the assessed process. |

| F | Fully achieved | > 85% to ≤ 100% achievement | There is evidence of a complete and systematic approach to, and full achievement of, the defined process attribute in the assessed process. No significant weaknesses related to this process attribute exist in the assessed process. |

| Level | Description | Process attribute | Rating |

| Level 0: Incomplete process |

The process is not implemented or fails to achieve its process purpose. | ||

| Level 1: Performed process |

The implemented process achieves its process purpose | PA 1.1: Process Performance | Largely |

| Level 2: Managed process |

The previously described performed process is now implemented in a managed fashion (planned, monitored and adjusted) and its work products are appropriately established, controlled and maintained. | PA 1.1: Process Performance PA 2.1: Performance Management PA 2.2: Work Product Management |

Fully Largely Largely |

| Level 3: Established process |

The previously described managed process is now implemented using a defined process that is capable of achieving its process outcomes. | PA 1.1: Process Performance PA 2.1: Performance Management PA 2.2: Work Product Management PA 3.1: Process Definition PA 3.2: Process Deployment |

Fully Fully Fully Largely Largely |

| Level 4: Predictable process |

The previously described established process now operates predictively within defined limits to achieve its process outcomes. Quantitative management needs are identified, measurement data are collected and analyzed to identify assignable causes of variation. Corrective action is taken to address assignable causes of variation. | PA 1.1: Process Performance PA 2.1: Performance Management PA 2.2: Work Product Management PA 3.1: Process Definition PA 3.2: Process Deployment PA 4.1: Quantitative Analysis PA 4.2: Quantitative Control |

Fully Fully Fully Fully Fully Largely Largely |

| Level 5: Innovating process |

The previously described predictable process is now continually improved to respond to organisational change. | PA 1.1: Process Performance PA 2.1: Performance Management PA 2.2: Work Product Management PA 3.1: Process Definition PA 3.2: Process Deployment PA 4.1: Quantitative Analysis PA 4.2: Quantitative Control PA 5.1: Process Innovation PA 5.2: Process Innovation Implementation |

Fully Fully Fully Fully Fully Fully Fully Largely Largely |

Further Reading

- Official Automotive SPICE website (download of all current Automotive SPICE documents).

- www.automotive-his.de website of Herstellerinitiative Software (HIS).

- [amazon_search design="2" width="300" market_place="" color_theme="Default" default_search_term="Automotive SPICE" search_index="All" columns="1" rows="3" outer_background_color="##BDBDBD" inner_background_color="" background_color="##BDBDBD" border_color="" header_text_color="#000000" linked_text_color="#365DA0" body_text_color="" shuffle_products="True" show_image="True" show_price="True" show_rating="True" rounded_corners="False"/]

: Advanced Vehicle Technology Competitions, via flickr.com • Automotive SPICE, VDA QMC Working Group 13 / Automotive SIG, .

Leave A Comment