The Notion Of Value In Agile And Lean Development

„Value“ in Lean Development/Manufacturing

In Lean Production, the term „Value“ is well known and established without relatedness to its Usage: Toyota Production System, TPS (Ohno 1988), Six Sigma, and Lean Software Development (Poppendick, Poppendick 2003).

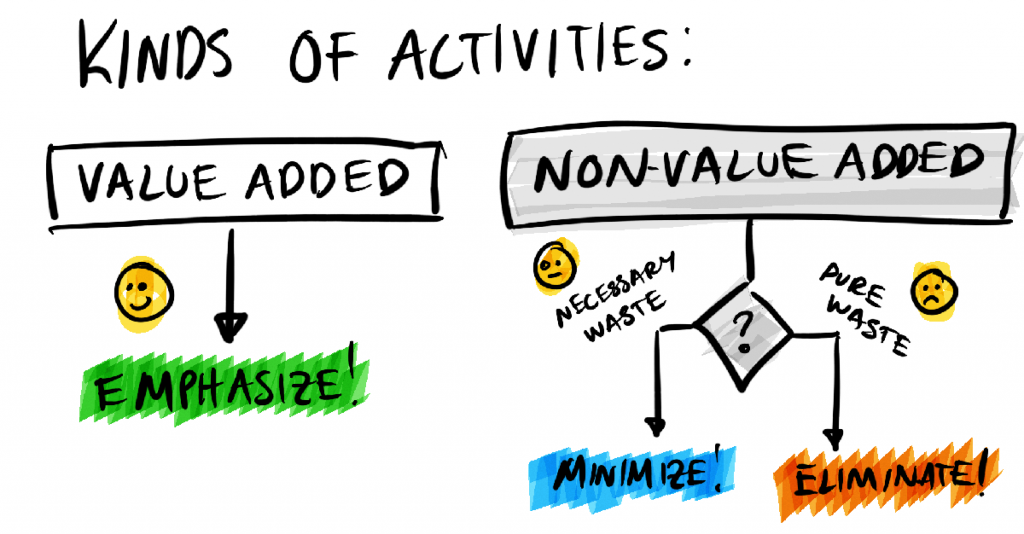

In Lean Development/Manufacturing Value is attached to „Value-adding“ and „non-Value-adding“ activities. Image, a Customer/User orders a Product. The manufacturer starts to work. First, he buys all materials needed (Value creation 1).

Then she performs all other activities to produce the Product. Certain activities will add Value to the work item, others not (Value creation 2-n). E.g., in the first place, the Value of an axis of a car to be built consists of material and Production costs. By additional welding or ironing activities, the axis becomes stronger, with more shock and temperature resistance – it becomes a premium. Instead, transporting the axis only from plant A to plant B is a non-Value-adding activity.

Mary and Tom Poppendick compared waste (aka non-Value-adding activities) in Lean Manufacturing and Lean Software Development (Poppendick, Poppendick 2003).

| Waste (Lean Manufacturing ) | Waste (Lean Software Development) |

| Inventory | Work Done Parallel |

| OverProduction | Extra Features ("Gold Plating") |

| Extra-processing | Relearning |

| Transportation | Handoffs |

| Waiting | Delays |

| Motion | Task Switching (Multitasking) |

| Defects | Defects |

The goal of Lean Manufacturing/Production is (1) from the business perspective to increase profit by eliminating all waste (all non-Productive activities), and (2) from the Customer perspective to minimize the customer waiting time from the time ordering the Product to the point of getting it shipped. Since (2) counts toward (1) increasing the manufacturer's profit:

In Lean, Value, Value-adding actions, and Value streams are strongly related to the monetary aspects of the Product.

– (see Exhibit 1).

Value Stream

Value Stream (Lean Manufacturing/Production)

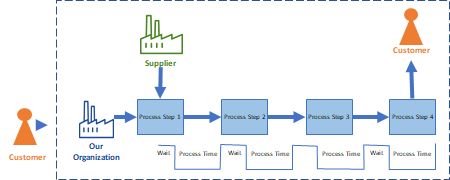

Value streams are part of the business ecosystem that describe how Stakeholders/Customers/Users receive Value from an organization. From an outside-in view, Value streams can be cross-mapped to business capabilities to describe what and how an organization must do to deliver Value to the Stakeholder.

A Value stream is the set of actions that take place to add Value to a Customer from the initial request through the realization of Value by the Customer.

A Value stream always begins and ends with the Customer. The goal is to improve time to Value by optimizing the whole Value stream.

Exhibit 1

Value-stream mapping is diagraming every step involved in the material and information flows needed to bring a Product from order to delivery. It is a fundamental tool used in continuous improvement to identify and eliminate waste. It clearly showcases the flow of goods from third-party vendors to Customers through your organization.

Toyota developed Value-stream mapping — which it calls a material and information flow diagram — and it is a critical part of the Toyota Production System. Value-stream mapping is one of the key Lean Six Sigma tools/techniques used to provide a detailed visualization of processes in an organization.

Value Stream (Agile Definition)

According to Jurgen Appelo, founder of Management 3.0 and entrepreneur, Value streams satisfy high and low-level jobs to be done. Instead of waiting for a Customer/User request (order), wait for Customer/User signals of interest. Therefore we have to improve the experience for Users as well, not only Customers.

A Value Stream is the set of actions needed to discover or deliver on a Job-to-be-Done basis a signal to the Customer/User Experience.

A Value Stream always begins and ends with a User or a Customer.

The goal is to improve the experience by optimizing the whole Value Stream.– (Appelo 2022)

Within this definition, Value streams start prior to a Customer or User request. The manufacturing organization has to observe the market resp. Customer continuously for her signals. And the Value stream finally ends when the User discards the Product and doesn't use it any longer — she “lays it off”.

„Value“ in Agile Product Development

Value is an important concept in Agile. However, in Agile Product Development, “Value” is interpreted differently than in Lean Production.

“The entire Scrum Team is accountable for creating a valuable, useful Increment every Sprint.”

— (Scrum Guide 2020)

Here, the focus is not on adding value-added activities essentially. Instead, the focus is on the Product's Usefulness.

Here, the focus is not on adding value-added activities essentially. Instead, the focus is on the Product's Usefulness.

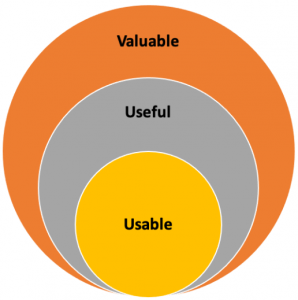

Samuel Adesoga distinguishes between "Usable", "Useful" and "Valuable" (Adesoga 2022, Oct. 20). A usable Product is one that is fit for use and there is a closely associated measure for Usability known as “Ease of Use”. Usefulness means to “find a use” for a Feature or Product. Value is focused on the point of view of the Customer.

"For a Product to be useful, it must be usable; and for a Product to be valuable, it must be useful."

— (Adesoga 2022, Oct. 20)

A "useful Product increment" can be created by Value-adding activities in the traditional sense (like additional ironing). But, what is much more important, is that a "useful Product increment" is not limited to Value-adding activities only.

Thus, in Agile Product Development, Value is not primarily related to monetary aspects (the more Features, the more Money). Instead, it is connected to the Product's Usefulness for the Customer/User Need instead. – The Product must be Fit for Purpose.

"Products have a Purpose, a Mission, a Goal."

— (Anderson 2017)

More about the value of Agile Development and Lean Development you find in this blog post.

Further Readings

- Adesoga, Samuel (2022, Oct. 20): Usable, Useful and Valuable. Scrum.org, 2022, Oct. 20. https://www.scrum.org/resources/blog/usable-useful-and-valuable.

- Anderson, David J., Zheglov, Alexei (2017): Fit for Purpose: How Modern Businesses Find, Satisfy, & Keep Customers. Blue Hole Press, 2017.

- Appelo, Jurgen (2022): unFIX. Workshop material, Sept. 13, 2022. München.

- Ohno, Taiichi (1988). Toyota Production System. New York, NY: Productivity Press, 1988.

- Poppendieck, Mary, Poppendieck, Tom (Poppendick, Poppendick 2003): Lean Software Development: An Agile Toolkit for Software Development Managers. Addison-Wesley Professional, 2003.

: Juraj Varga via PixaBay.com • Kevin Huynh • Samuel Adesoga, Scrum.org, .

Leave A Comment